A hydraulic cylinder is probably the most underrated mechanical inventions, it is so simple yet can perform so much work. It is this simplicity that can be deceiving when making repairs, especially quality repairs.

The devil is in the details. While most shops that can successfully take a cylinder apart can reseal a cylinder can make a successful repair, commonly that repair will only last a short period of time. This is because the science behind how seals work in conjunction with surface finishes is ignored, a critical detail.

To understand this, first we must understand how seals work. Elastic seals, the most common type of seal used in the modern hydraulic cylinder, work because hydraulic fluid pressure energizes the seal, pressing it against the metal surface on which it seals. This in turn creates friction against the seal and sealing surface as the cylinder is extended and retracted. Therefore, the sealing surface, whether it be the cylinder tube, or the rod is so critical.

To understand this, first we must understand how seals work. Elastic seals, the most common type of seal used in the modern hydraulic cylinder, work because hydraulic fluid pressure energizes the seal, pressing it against the metal surface on which it seals. This in turn creates friction against the seal and sealing surface as the cylinder is extended and retracted. Therefore, the sealing surface, whether it be the cylinder tube, or the rod is so critical.

Theoretically, a perfectly smooth finish would provide the optimal sealing surface. The problem with perfectly smooth finish is that it will cause premature wear on the seal. The friction placed on an energized seal is mitigated lubrication, and a perfectly smooth surface does not allow for lubrication between the seal and sealing surface.

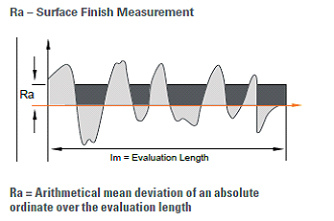

In hydraulics, the most common method we use to measure surface finish is Ra, which can be considered a measurement of roughness, and is typically measured in micro inches, and one micro inch is one-millionth of an inch. If we were to look at the surface of a sealing surface through a microscope, we would notice that there “peaks and valleys”, and because we are measuring in micro inches, those “peaks and valleys” are quite small. Even though this roughness is very small, it is enough that a very small amount of hydraulic fluid gets between the seal and sealing surface, thus providing lubrication to the seal. A finish that is to rough will allow to much fluid to pass between the seal and sealing surface, and finish that is too smooth will not allow enough fluid between the seal and sealing surface. The surface finish must be in predefined range, and that range is quite small.

In hydraulics, the most common method we use to measure surface finish is Ra, which can be considered a measurement of roughness, and is typically measured in micro inches, and one micro inch is one-millionth of an inch. If we were to look at the surface of a sealing surface through a microscope, we would notice that there “peaks and valleys”, and because we are measuring in micro inches, those “peaks and valleys” are quite small. Even though this roughness is very small, it is enough that a very small amount of hydraulic fluid gets between the seal and sealing surface, thus providing lubrication to the seal. A finish that is to rough will allow to much fluid to pass between the seal and sealing surface, and finish that is too smooth will not allow enough fluid between the seal and sealing surface. The surface finish must be in predefined range, and that range is quite small.

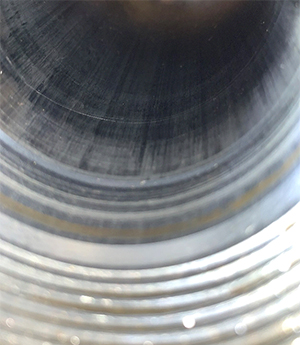

It is a common detail that is overlooked by a great many people when repairing hydraulic cylinders. As a hydraulic cylinder is used, the friction between the seal and sealing surface begins to wear, and this surface becomes smoother, not to mention may show wear marks or other signs of damage. If attention is not paid to finish of the sealing surface during repair, the new seals installed in the cylinder will fail in a short period of time. It is not a detail that Montana Hydraulics overlooks.

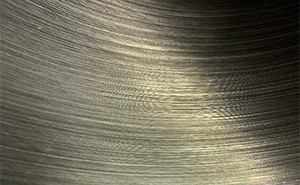

When Montana Hydraulics repairs cylinders we hone the tubes on our tube hone, polish the cylinder rods to optimal condition, and pay especially close attention to these critical details. We use a profilometer to measure the surface finish to ensure that repaired parts are within specification and can ensure years of reliable service on repaired cylinders. Let’s face it, hydraulic fluid leaks are costly, and down time is even costlier, much costlier than having a quality repair performed by Montana Hydraulics. Our quality minded technicians fully test every cylinder after repairs are made, follow a strict checklist to ensure that materials and parts meet specifications, and back that repair with a warranty that can’t be matched. You trust your equipment to work for you, trust Montana Hydraulics to make reliable repairs to keep your equipment working.

When Montana Hydraulics repairs cylinders we hone the tubes on our tube hone, polish the cylinder rods to optimal condition, and pay especially close attention to these critical details. We use a profilometer to measure the surface finish to ensure that repaired parts are within specification and can ensure years of reliable service on repaired cylinders. Let’s face it, hydraulic fluid leaks are costly, and down time is even costlier, much costlier than having a quality repair performed by Montana Hydraulics. Our quality minded technicians fully test every cylinder after repairs are made, follow a strict checklist to ensure that materials and parts meet specifications, and back that repair with a warranty that can’t be matched. You trust your equipment to work for you, trust Montana Hydraulics to make reliable repairs to keep your equipment working.